Kantgaragen-Palast in Berlin – structural analysis of Europe’s oldest multi-storey parking facility

The Kantgaragen-Palast, built between 1930 and 1936 and listed as a historic building monument since 1991, is Europe’s oldest multi-storey parking facility that is still in operation. Krebs und Kiefer Beratende Ingenieure im Bauwesen GmbH has carried out an analysis of the condition of the building and a computational study of its load-bearing structure.

The Kantgaragen-Palast, built between 1930 and 1936 and listed as a historic building monument since 1991, is Europe’s oldest multi-storey parking facility that is still in operation. Krebs und Kiefer Beratende Ingenieure im Bauwesen GmbH has carried out an analysis of the condition of the building and a computational study of its load-bearing structure.

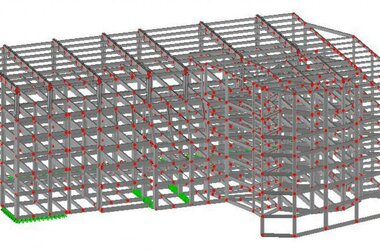

The multi-storey parking facility on Kantstraße consists of a reinforced concrete skeleton with a total of seven floors, each with single-axis pre-stressed slabs, three-bay secondary downstand beams and continuous main downstand beams in a longitudinal direction. The loads from the parking floors are transferred by columns which are mostly regularly positioned except over the vehicle entrance to the facility.

On the street side, the façade of the Kantgarage from the 1st to the 5th floor includes a steel and glass construction around 9,5 m wide; this consists of continuous NP 80 pillars with façade bars at around the middle of each floor level.

Initially, the Kantgarage was only built as far as the 4th floor. In 1936 and 1937, an additional level was added using a pre-stressed reinforced concrete frame transverse to the direction of the building; this is around 5 m high and 20 m wide, with tension members in the upper intermediate level and continuous reinforced concrete purlins in a longitudinal direction.

The skeleton construction is stiffened by the reinforced concrete cores of the staircases and two further transverse reinforced concrete walls.

The ramp construction in the Kantgarage is particularly noteworthy, since it includes the first nested spiral ramps to be built in Europe.

Computational study of structural stability

The study of the structural stability of the reinforced concrete load-bearing structure of the Kantgarage was carried out using a 3D calculation model based on the imposed loads specified in 1929, which, with the exception of the ramp areas, roughly correspond to today’s requirements: for the slab over the basement level, a load per unit area of 8 kN/m² and alternatively two individual loads of 10 kN to 25 kN depending on the building component were assumed, and for the slabs over the ground floor and above-ground floors, a load per unit area of 3 kN/m².

The material qualities used in the study of the stability of the reinforced concrete load-bearing structure were initially taken from the structural calculations produced in 1929. According to these, “high-quality cement” was used in the production of the concrete and commercial steel (St 37) was used for the reinforcement. The original calculations for the reinforced concrete structure were carried out in accordance with the German regulations of 1925 on the construction of reinforced concrete and concrete structures and were based on a permissible tension in the concrete of 45 kg/cm² to 60 kg/cm² (depending on the building component) and in the steel of 1200 kg/cm².

As a result of the computational study, it is possible to determine (among other things) the degree of utilization of the columns. As expected, these values exceed the permissible limit of 1,0 in locations with irregular load-bearing structures which were difficult to calculate using the methods of the time, e.g. over the entrance area. Also, because the tension members in the uppermost intermediate level were not pre-stressed, the two-hinged frames of the 5th floor do not fulfill the calculated requirements for load-bearing capacity.

Damage assessment and materials testing

To assess the condition of the Kantgarage, all damage to load-bearing elements was systematically recorded and mapped and random samples of the materials were tested. The reinforced concrete slabs over the basement level, in the transit areas and in areas subject to heavy loads (e.g. at bearings which were not taken into consideration in the original calculations) showed extensive cracking, moisture penetration, salt efflorescence and spalling over the reinforcement. Tests on random samples of material from the slabs and beams showed that the alkaline environment necessary to protect the reinforcement steel from corrosion no longer exists, due to the chemical reaction between the hydrated cement and atmospheric carbon dioxide which has extended into the interior of the building components. Furthermore, the chloride content of the concrete significantly exceeds the critical limit necessary to avoid pitting of the steel reinforcement. Despite this, the cross-sections of the reinforcement in the rising building components show relatively minor losses.

The costs for repairing the damage are now being calculated on the basis of the mapped damage, the results of the tests on random samples of the materials and the structural calculations for the reinforced concrete construction.