Last section of the A 96 Munich - Lindau motorway opened for traffic

After 40 years of planning and 32 years of construction, the goal was reached: on 23.11.2009, the last section in the A 96 Munich – Lindau motorway was opened for traffic. The opening of the new Gebrazhofen – Dürren section has eliminated a congestion- and accident-prone bottleneck from the German road network.

Together, the A 8 and the A 96 form an efficient connection between Rosenheim and Lindau. In combination with the A 7, there is now an excellent north-south axis between Scandinavia and Austria that also has connections with Switzerland and Italy.

After 40 years of planning and 32 years of construction, the goal was reached: on 23.11.2009, the last section in the A 96 Munich – Lindau motorway was opened for traffic. The opening of the new Gebrazhofen – Dürren section has eliminated a congestion- and accident-prone bottleneck from the German road network.

Together, the A 8 and the A 96 form an efficient connection between Rosenheim and Lindau. In combination with the A 7, there is now an excellent north-south axis between Scandinavia and Austria that also has connections with Switzerland and Italy.

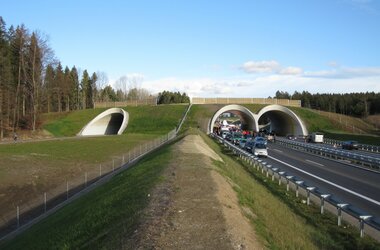

The 96/209 environmental bridge over the A 96 and K 8025 road near Gebrazhofen is the most important structure on the new Gebrazhofen – Dürren section. KREBS+KIEFER Karlsruhe carried out the design and tender planning for this structure.

It consists of an earth embankment that spans the A 96 with a two-cell arched frame structure and the K 8025 with a single-cell arched frame structure.

Although the structure is situated far from the nearest residential areas, it involved a level of difficulty that is seldom seen even in inner-city construction projects.

During the entire construction period, large volumes of traffic had to be conducted through the construction area. This was achieved by means of several provisional traffic arrangements and temporary structures and a carefully thought-out space management system which required very detailed consideration of the individual stages of construction, even during the design phase.

The construction area was located in a rainwater retention basin which had to remain in operation during the initial phases of construction. A solution based on several provisional drainage systems was developed; this made it possible for construction to progress almost independently of the operation of the rainwater retention basin.

The subsoil, which consisted of soft glacial deposits down to great depths, and the pressurized ground water, which in some areas had a head of pressure above ground level, presented major challenges in the construction of stable foundations for the environmental bridge embankment, the roads and the bridge structures themselves. By combining soil replacement and vibro displacement columns, a safe and cost-effective solution was realized.

Since only very limited amounts of high-quality earth were available within the overall project, but lower-quality earth was available in large quantities, a sophisticated earth construction concept was developed which minimized both the quantity of external material that had to be purchased and the amount of excess earth requiring disposal.

To adapt the environmental bridge to the very varied topography of the area, it was constructed as a multi-layer digital landscape model that took into consideration the individual construction phases with their diverse traffic arrangements and temporary structures. This allowed the quantities involved in the earth construction and specialized heavy construction measures to be estimated with the necessary degree of accuracy.

At the owner’s request, the design loads for the structures were based on Swiss norms. The design itself was produced in accordance with German norms, which made it possible to use relatively thin shells.